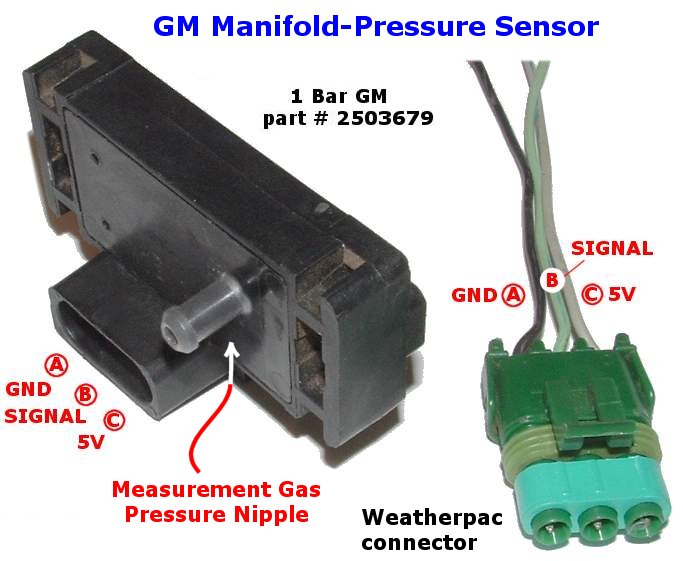

The image [enlarge it] shows a 1 bar GM MAP sensor designed for normally aspirated engines with electronic fuel injection (EFI). As well, you can see the green Weatherpak mating connector showing what pins to use.

You can see the measurement-gas nipple that typically connects to the engines inlet manifold. The sensor measures pressure from zero to 1 bar or atmospheric pressure. This means it can be thought of as a vacuum sensor that measures from -1 bar to 0, or to atmospheric pressure. GM make other sensors that have a 2 bar range (from -1 Bar to +1 Bar = #16009886) a 3 bar range (from -1 Bar to +2 Bar = #16040749), and even one that simply measures variations of barometric pressure (from -1 Bar to +2 Bar = #16040749).

GM MAP sensors can be obtained from auto wrecker and first started appearing in Australia around 1988 on GM's J-car - the JE 2.0 GM-EFI Camira (not the Bosch-EFI 1.6/1.8 motor) and later, on the VN Commodore. In the USA they have been around since the mid 1980s. If possible, get the Weatherpak loom connector with the MAP sensor.

Most Tech Edge controllers also collect data in the form of pulses (RPM & VSS) and voltage (USER and TC inputs). Many newer controllers also provide a source of 5 Volts to power external devices such as the GM MAP sensor. It's a simple matter to wire the MAP sensor and the example is for the 3A1 controller - the relevant connection points are shown in the image and decribed below:

1. Wire the MAP sensors A pin to a GND point near the Tech Edge controller (Y5-pin9 for the 3A1)

2. The C pin goes to 5 Volts - on newer Tech Edge controllers this comes from the controller (Y5-pin8 for the 3A1).

3. The MAP sensors B pin is the output that goes to a USER input (USER1 = Y2-pin8 for the 3A1).

To test the setup you should have a voltmeter to first determine if you can see a varying voltage between the GND point and the USER input on the controller. A blip of the throttle should see the meter move. When you're sure you have a signal to measure then you can start looking for the data using logging software, or after setting up a display, seeing your manifold vacuum (see the software section for more info). The third view on Tech Edge displays (LD02, LA1, LX1, etc.) defualts to the USER1 input displayed as a percent of 5.00 Volts.